![]() Are you wondering if your business would benefit from an investment in FAB software?

Are you wondering if your business would benefit from an investment in FAB software?

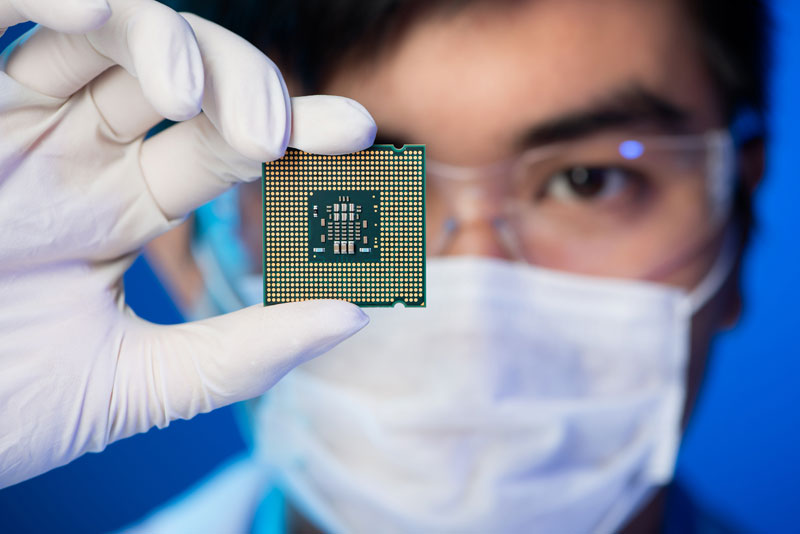

As today’s semiconductor manufacturing technologies evolve, systems integration for your FAB facility is a critical way to keep up with the competition.

Let’s look at a few ways FAB software impacts semiconductor manufacturing.

What are FABs?

A FAB uses a clean room environment within a manufacturing plant. The plant manufactures integrated circuits (or semiconductors) using raw silicon wafers.

You’ll find independent FABs that produce semiconductors. They ship completed pieces to other companies for use in that company’s products.

You’ll also find companies with internal FAB labs. They make their semiconductors for use within the company’s products.

Whether you have your FAB lab or you outsource to another company, FAB software provides benefits throughout the semiconductor manufacturing process.

Reduce Costs

As an American chip manufacturer, what if you could save money on your fabrication process? Your bottom line improves.

With FAB software monitoring the production process, your system becomes more automated. There is less room for human error when using software to watch for inaccuracies in the line.

Furthermore, when software includes specs for the process from start to finish, quality matches with every piece.

Increase Productivity

Fewer errors mean fewer interruptions or faulty products to toss and redo. Quality control becomes less of an issue and more of an asset.

Where human monitoring in your FABs application process allows for errors, even with the best operators, software automation helps reduce human error.

With fewer mistakes comes increased speed and accuracy. This results in increased productivity and a better quality product.

Process Tracking and Analysis

You’ll learn from mistakes and continually analyze processes for improvement when using FAB software.

There’s no need to guess what went wrong and to predict how improvement might affect the production process and your product’s results.

FAB software tracks behavior, history and helps show you where production adjustments help improve your business.

Testing Before Production

As a semiconductor manufacturer, you’re familiar with designing and producing sample products before rolling out a mass quantity.

With FAB software, you’ll design a product and test it in a virtual environment. This saves the time and expense of producing physical pieces.

With digital design capabilities, you’ll save money on expensive prototypes. You’ll also take your product from design to production faster.

Automating your systems helps get your product to market quicker than the competition.

Automated Semiconductor Manufacturing for Your Future

It does sound like something out of a futuristic movie, but the future of semiconductor manufacturing is here with FAB software solutions.

Manufacturing isn’t the only industry benefitting from software automation.

We work across several industries to provide integrated solutions. From manufacturing to health care to government, let us find an automated solution for you.

We provide products and services across the globe. Contact Us to get started on a more efficient and profitable business through automation and integration.

Established in 1994, Superior Automation provides cutting-edge automation solutions for customers around the globe, ensuring quality control and meeting industry safety and compliance standards.