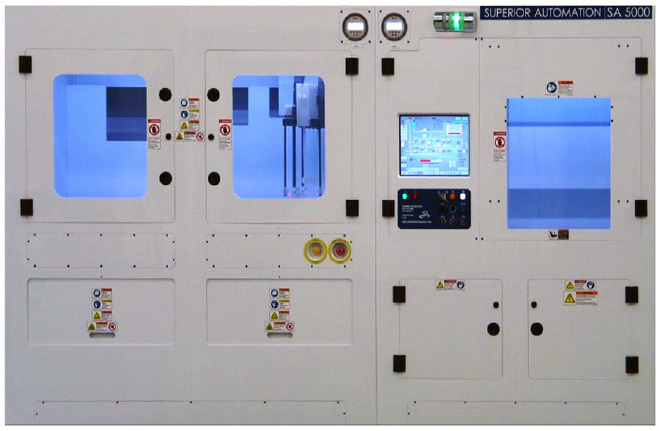

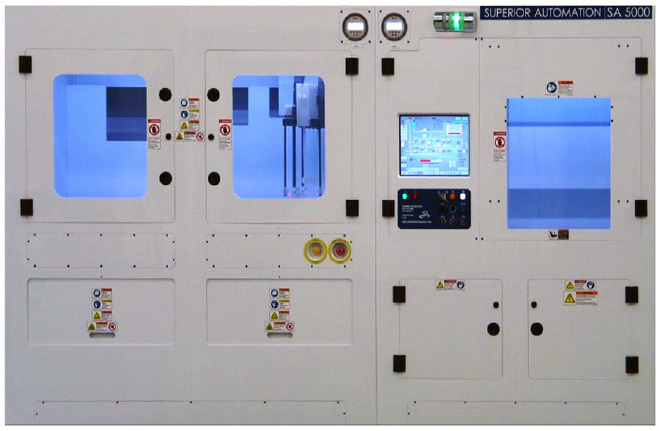

SA 5000-AWP Fully-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- 50 to 400 Wafer Buffer Queue

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

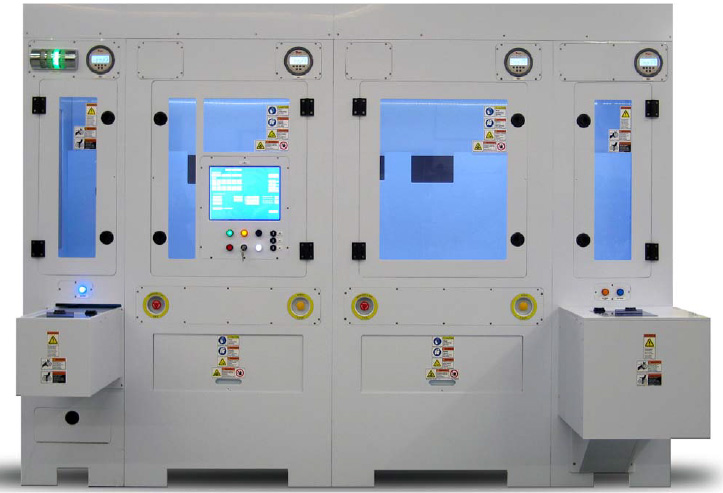

SA 5000-HDM Fully-Automated

Benefits

- Pre and Post Sputter Cleaning and Etching

- Cassette-less Processing

- Automatic Chemical Concentration Controls

- Optimized Process Performance

- Maximum Throughput 500-2000 DPH

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 25 to 100 Wafer Lots

- 27mm to 95mm Disks

- Dry In-Dry Out/Wet In-Dry Out Process

- Lot Tracking via RFID System

- Bi-Directional Processing

- Parallel-HOM Size Lot Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized HOM Handling

- Equipment Host Interface: Database/ MES

- Compliant Standards CE, FM, NFPA, NEC, SEMI 52, 58, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- 100 to 400 HOM Buffer Queue

- Dry or Wet Input/Output Conveyors

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 3.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Drying Technologies

- Custom Automation/Options per your Request

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 5000-SST Fully-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Dedicated Fire Suppression System

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- Advanced Rapid Heating System

- Automatic Chemical Fill and Tank to Tank Transfer

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards ATEX, Class I dif. II, CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Photo-Electric Etching

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Vertical or Horizontal

- 50 to 400 Wafer Buffer Queue

- Class 10 Mini Environment

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- Products and Services

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 5000-SWP Fully-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Single Wafer Processing

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Wafer Processing

- Parallel-Wafer Size Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Solvent Strip

- Micro/Nano Strip

- NEG Resist Strip

- POS Resist Strip

- Metal Lift-Off

- Debonding

- Ink Removal

- Developing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- 50 to 400 Wafer Buffer Queue

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Single or Double Sided Single Wafer High Pressure Spray Station

- Real Time IN-Line Chemical Metrology System

- Cassette-less Wafer Processing

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

AURORA Electroless Plating Fully-Automated

Benefits

- Thicknesses from Angstroms to Hundreds of Microns

- Maximum Throughput Batch Plating

- Automatic Deposition Rate Calculation

- Optimized Process Performance

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Pretreatment, Electroless Plating, Rinse and Dry

- 5 to 50 Wafer Lots

- 25mm to 200mm Wafers

- Dry In-Dry Out Process

- Cassette-less Wafer Processing

- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Au Plating (Gold)

- Cu Plating (Copper) Seed Layer, Barrier, Pad, RDL, Pillar

- Ni Plating (Nickel)

- Pd Plating (Palladium)

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- 5 to 400 Wafer Buffer Queue

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 2000-SL Semi-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Rotational Tank to Tank Transfer

- Multi-Tank Operation

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Multi-Step Processing Recipes

- Multi-Wafer Size Lot Processing

- Advanced Intelligent Process Controls

- Multi-Motion Agitation Profiles

- Advanced Wafer Handling

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Automated Load Port Door

- Class 10 Mini Environment

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- IN-Line Chemical Metrology System

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- GEM/SECS Host Interface

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 2000-RT Semi-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Front to Back Tank to Tank Transfer

- Multi-Tank Operation

- 25 to 1 00 Wafer Lots

- 75mm to 300mm Wafers

- Multi-Step Processing Recipes

- Multi-Wafer Size Lot Processing

- Automated Load Port Door

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- GEM/SECS Host Interface

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 2000-LT Semi-Automated

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Front-to-Back Tank-to-tank Transfer

- Multi-Tank Operation

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Multi-Step Processing Recipes

- Multi-Wafer Size Lot Processing

- Advanced Intelligent Process Controls

- Multi-Motion Agitation Profile

- Advanced Wafer Handling

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Automated Load Port Door

- Class 10 Mini Environment

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- IN-Line Chemical Metrology System

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- GEM/SECS Host Interface

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 2000-HT Semi-Automated

Specially Designed for Sapphire Etching Silicon Carbide Etching High Temperature Etching Up to 425 deg.

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Front to Back Tank to tank Transfer

- Multi-Tank Operation

- Advance Safety Features

- High Temperature Quartz Processing Vessel (Rating 425 deg. C)

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Automatic Chemical Fill

- Automatic Chemical Mixing Dosing/ Spiking

- Multi-Step Processing Recipes

- Multi-Wafer Size Lot Processing

- Multi-Lot Processing

- Advanced Intelligent Process Controls

- Multi-Motion Agitation Profile

- Optimized Wafer Handling

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Etching

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Quartz Carriers

- Cassette to Carrier Wafer Transfer

- Automated Load Port Door

- Class 10 Mini Environment

- Hot Dl Water Rinse

- Cassette-less Wafer Processing

- Drying Technologies

- GEM/SECS Interface

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 1000-SST Solvent Strip Tool Manual

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Dedicated Fire Suppression System

- Advanced Intelligent Process Controls

- Compliant Standards ATEX, Class I dif. II, CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Solvent Strip

- Micro/Nano Strip

- NEG Resist Strip

- POS Resist Strip

- Metal Lift-Off

- Debonding

- Ink Removal

- Developing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Class 10 Mini Environment

- Automatic Chemical Fill

- Tank to Tank Transfer

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Single or Double Sided Single Wafer High Pressure Spray Station

- Real Time In-Situ Chemical Metrology System

- GEM/SECS Host Interface

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- Equipment-Host Connectivity Solutions via SA- GemStation Software (GEM and non-GEM Compliant Tools)

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA 1000 Manual Electro Plater

Benefits

- Optimized Process Performance

- Superior Process Uniformity

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 1 to 8 Plating Cells

- Horizontal or Vertical Plating Cells

- 25mm to 300mm Wafers

- Multi-Wafer Processing

- Parallel -Wafer Size Processing

- Advanced Intelligent Process Controls

- Programmable Power Supply: Voltage, Current, Ramp Rate, Pulse Width

- Multi-Step Recipe: Pulse (FWD/REV) or DC

- Superior Temperature Controls 15C-80C

- Programmable Recirculation Flow Rate

- Reclaimable Process Chemistry

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, P39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Electro Plating

- Electro-Magnetic Plating Cells

- Fountain Plating Cells

- Paddle Plating Cells

- Au Plating (Gold)

- Cu Plating (Copper)

- Co Plating (Cobalt)

- Ni Plating (Nickel)

- Ni/Co Plating (Nickel/Cobalt)

- NiFe Plating (Nickel Iron)

- NiFeCo Plating (Nickel/Iron/Cobalt)

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Class 10 Mini Environment

- Automatic Plating Rate Calculation

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Add Back/Dosing/Spiking

- Single and Multi Wafer Fixtures

- Multi Ch. Segmented Fixtures

- Custom Fixtures

- Multi Channel Power Supplies

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- Equipment-Host Connectivity Solutions via SA- GemStation Software (GEM and non-GEM Compliant Tools

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA1000 Manual

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Advanced Intelligent Process Controls

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Class 10 Mini Environment

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Fixed or Multi-Frequency Megasonics’s 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonic’s 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- Equipment-Host Connectivity Solutions via SA- GemStation Software (GEM and non-GEM Compliant Tools

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

SA100 LAB-FAB Fume Hood Stations

Benefits

- Low Cost

- Optimized Process Performance

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Standard Features

- Large Working Deck

- LED Deck Lighting

- Above Deck Storage Shelf

- Exhausted Chemical Bottle Storage Area

- Above Deck Empty Bottle Storage

- N2 & Dl Water Guns

- Flexible Process Controls

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Flexible Options

- Standard and Custom Applications

- Class 10 Mini Environment

- Dedicated Fire Suppression Systems

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- Hot Plates

- Single Wafer Spin Processors (Acids/Bases/Photo-Resist/Solvents)

- Single or Double Sided Single Wafer Scrub Station

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering