MEMs is an often used term in the world of technology.

MEMs is an often used term in the world of technology.

You may be wondering what this term actually means and what purposes these devices serve.

Odds are, you’re already familiar with MEMs devices and don’t even know it. After all, this technology is used just about everywhere these days.

Here is what you need to know about MEMs technology — what it is, how it’s made, and what it can be used for.

What is MEMs Technology?

Depending on where you are in the world, the meaning of MEMs may change, but the technology itself remains the same.

In some parts of the world, MEMs can stand for Micro-Electro-Mechanical Systems. In others, MEMs stands for Microsystems Technology. MEMs can also stand for Micromachines — which is the simplest definition for what they are.

In the United States, however, these devices are generally referred to just as MEMs.

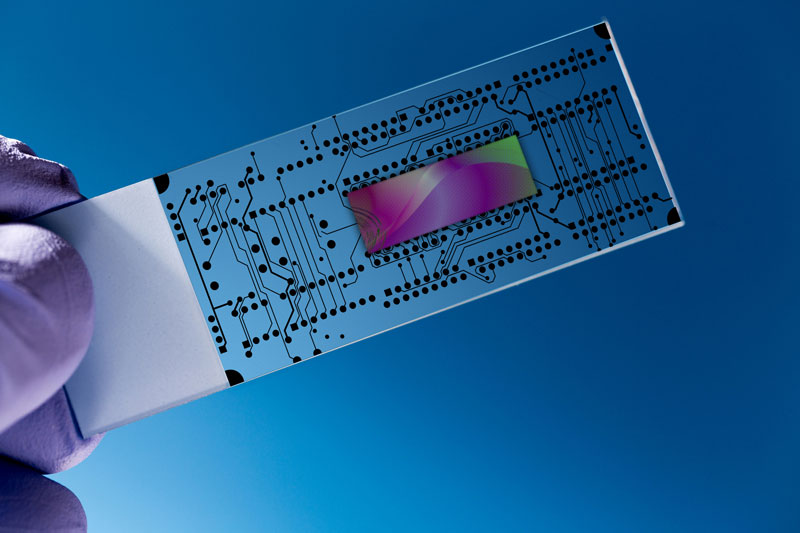

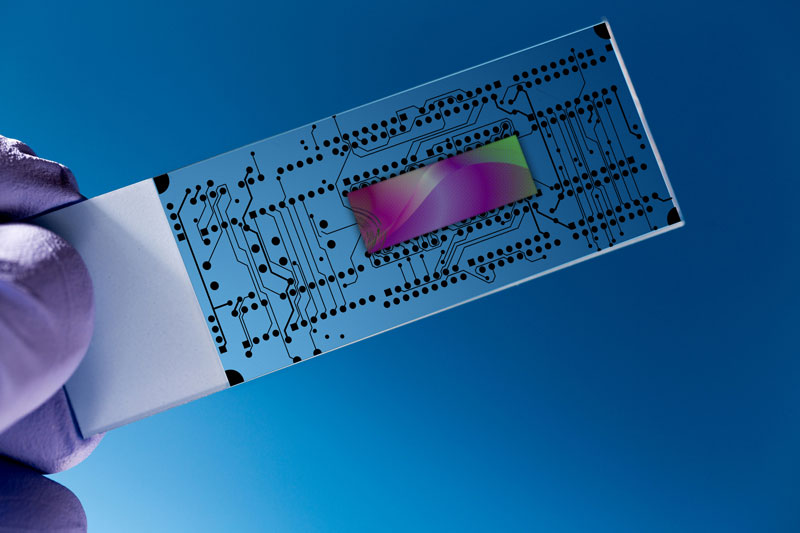

MEMs devices are incredibly small mechanical and electro-mechanical structures. Due to their uniquely minuscule statures, they serve a wide variety of purposes. Undoubtedly, it is their size that sets them apart from other modern marvels.

Size wise, MEMs devices can range from just a few millimeters to below a single micron. MEMs devices can be so minute that there are many that are smaller than the width of a human hair.

For a device to earn the classification of a MEMs device, it must have the ability to perform a mechanical function. However, the presence of mechanics does not equate to movement.

There are scores of MEMs devices that feature elaborate electromechanics and many moving parts. All of this complexity despite their diminutive size.

At the same time, many MEMs devices consist of comparatively simple structures that have no movable elements.

What Does MEMs Technology Do?

Because of its size, manufacturers are currently using MEMs technology to perform a wide array of tasks. Currently, some of the most common uses for MEMs technology includes micro heat exchangers and pressure sensors. Infrared detectors can also contain MEMs technology.

MEMs technology is also used in micro-mirror arrays for high-definition projectors as well as in ink jet printer heads.

The primary MEMs technologies available are very close to the same elements you would find in average-scale machinery. These components include microelectronics, microsensors, microactuators, and microstructures.

In the not so distant future, manufacturers will be able to integrate these components into a single microchip. However, current technology restricts these devices to individual uses.

How are MEMs Devices Made?

Due to the usual size of MEMs devices, manufacturers cannot create them using regular machined methods.

Manufacturers create MEMs devices using microfabrication technologies. These methods are very similar to those used in the creation of integrated circuits.

This method of production is relatively low cost. Therefore, the popularity of MEMs devices, such as silicon-based sensors, has grown swiftly over the last few years, which, in turn, has caused the market for these types of devices to grow as well.

Your Guide to MEMs Technology

MEMs technology is already an expansive field that is only going to keep growing.

The possible applications for this kind of technology are endless. Plus, you can be sure that we’ll be there for every new development.

The MEMs community requires specialized solutions and that’s where we come in. Contact us for more information about our work in MEMs fabrication.

Established in 1994, Superior Automation provides cutting-edge automation solutions for customers around the globe, ensuring quality control and meeting industry safety and compliance standards.