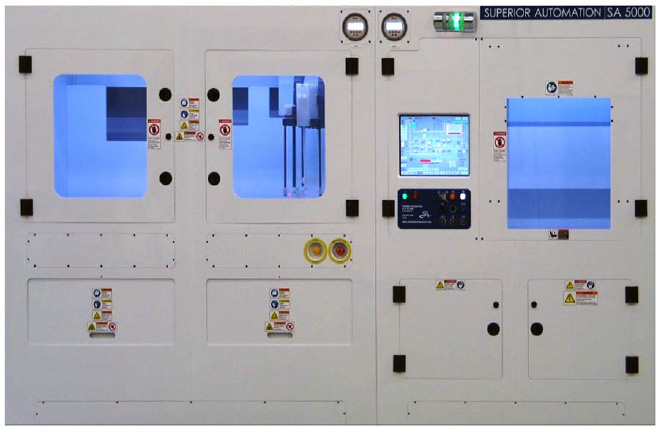

Our line of fully automated benches, the SA 5000’s, is a long-standing solution for a variety of applications within the semiconductor industry and beyond. The SA 5000 line leaves the smallest footprint available and has the lowest cost of ownership all while keeping it easy to use and easy to maintain.

Superior Automation specializes in making our products extremely flexible and customizable. Below are a few examples of tools we are currently supporting in fabs across the world.

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Flexible Options

- Standard and Custom Applications

- 50 to 400 Wafer Buffer Queue

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Cassette-less Wafer Processing

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- IN-Line Chemical Metrology System

- Automatic Chemical Fill

- Automatic Chemical Mixing-Dosing/Spiking

- Multi-Motion Agitation Profiles

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards CE, FM, NFPA, NEC, SEMI S2, S8, SOP39

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Flexible Options

- Standard and Custom Applications

- 50 to 400 Wafer Buffer Queue

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Single or Double Sided Single Wafer High Pressure Spray Station

- Real Time IN-Line Chemical Metrology System

- Cassette-less Wafer Processing

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Stripping

- Texturing

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Dedicated Fire Suppression System

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- Advanced Rapid Heating System

- Automatic Chemical Fill and Tank to Tank Transfer

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards ATEX, Class I dif. II, CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Flexible Options

- Standard and Custom Applications

- Vertical or Horizontal

- 50 to 400 Wafer Buffer Queue

- Class 10 Mini Environment

- Automatic Process Time Calculation based on Etch Rate and Target Thickness Removal

- Automatic etch rate/target thickness lookup from MES, SPC, and/or Metrology results data

- Fixed or Multi-Frequency Megasonics 750kHz to 2.0mHz

- Fixed or Multi-Frequency Ultrasonics 25kHz to 430kHz

- Products and Services

- In Tank Dedicated Agitators 0-80 Cycles Per Min

- Bi-Directional Chemical Recirculation Flow

- Single or Double Sided Single Wafer Scrub Station

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Photo-Electric Etching

- Stripping

- Texturing

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering

Standard Features

- 25 to 100 Wafer Lots

- 75mm to 300mm Wafers

- Dry In-Dry Out Process

- Bi-Directional- Multi-Lot Processing

- Parallel-Wafer Size Lot Processing

- Dedicated Fire Suppression System

- Class 10 Mini Environment

- Advanced Intelligent Process Controls

- Advanced Intelligent Process Scheduler

- Advanced Rapid Heating System

- Automatic Chemical Fill and Tank to Tank Transfer

- Optimized Wafer Handling

- 100% GEM Compliant

- Compliant Standards ATEX, Class I dif. II, CE, FM, NFPA, NEC, SEMI S2, S8, SOP 39

Benefits

- Optimized Process Performance

- Maximum Throughput

- Optimized Process Flexibility

- Reduced Energy Consumption

- Reduced DIW-Chemical Consumption

- Maximum Chemical Life

- Flexible Chemistry Applications

- Maximum Reliability

- Maintenance Friendly

- Easy to Use, Easy to Maintain

- Smallest Footprint Available

- Easy Installation

- Lowest Cost of Ownership

Flexible Options

- Standard and Custom Applications

- 5 to 400 Wafer Buffer Queue

- Drying Technologies

- Unlimited Automation

- Unlimited Options

Industries

- Semiconductor

- Micro/Nano Electronics

- Compound Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLEO

- Optics

- MEMS

- CPV

Applications

- Cleaning

- Developing

- Etching

- Electro-Plating

- Photo-Electric Etching

- Stripping

- Texturing

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated and Manual

- Bulk Chemical Distribution Systems

- Bulk Chemical Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- OEM Wet Process Equipment Reconditioning and Upgrades

- Applications Engineering