Category: Blog

-

Fire Safety Issues With Wet Benches

Fire safety on industrial sites is an important issue. The National Fire Protection Association found that every year, there are over 37,000 fires at industrial and manufacturing facilities. Not only do these disasters cost companies money, but they cost lives. Industrial fires are not always preventable, but fire safety awareness greatly reduces the risk of…

-

Wet Bench Research: When’s the Best Time for a Retrofit?

Wet benches are a very important part of your business, and it goes without question that you want to keep yours in the best working condition possible. That is why it is very important that you consider retrofitting your wet bench. Retrofitting brings with it a whole list of benefits to help make your work…

-

How to Determine the Wafer Size Needed for Your Wet Benches

Unless you work in an industry that uses wet benches, chances are that you may have never heard of them before. However, a wet bench plays an important role in industrial automation and even in modern-day scientific research projects. They clean debris and scrape away the film of a base or acid from the wafer…

-

A Quick Guide to Handling Chemical Waste

Handling chemical waste with care is important, not only for your safety but the safety of others. Hazardous material can have an impact on the environment and the health of people. You may be in a position that requires knowing how to deal with potentially dangerous chemicals. This process means understanding basic toxic waste management…

-

The 5 Major Benefits of Retrofitting a Wet Process System

No matter what type of wet process system you have, there are a number of benefits that come with retrofitting. We narrowed it down to just 5 that we want to share with you today. Keep reading to find out more about why you should retrofit your wet process equipment. 1. Improve Machine Reliability New…

-

How Can a Turnkey System Address All of Your Wet Bench Needs?

A wet bench is an invaluable tool for process engineers and chemists. You can use wet benches for wet etching, a process to keep your wafers and devices clean. They’re different from litho benches, which are for resist processing. However, if you’re looking for a wet bench, what do you need to keep in mind?…

-

4 Industries That Benefit from Systems Integration

Businesses are taking on a life of their own through the power of systems integration. In fact, in 2017 companies spent $394 billion on IT consulting and systems integration equipment. Systems integration allows companies to create a cohesive automated flow for the numerous projects within their business. This option saves money, time, and relieves bottlenecks…

-

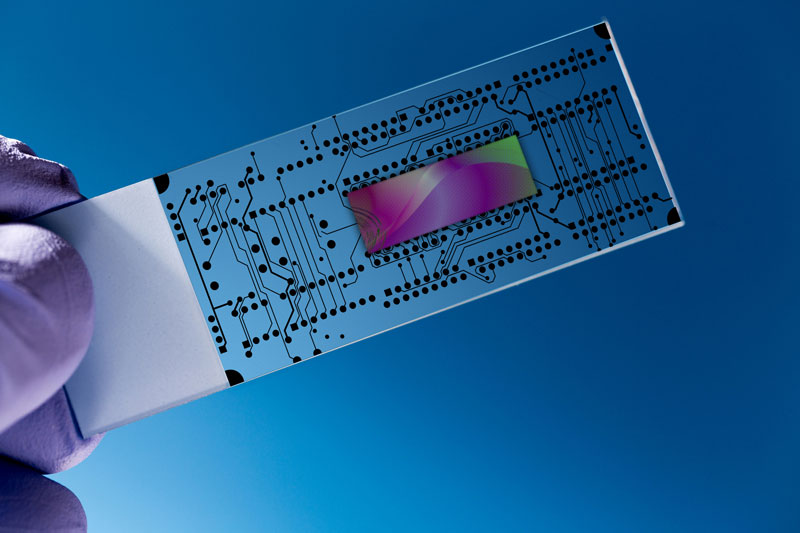

What is MEMs Technology?

MEMs is an often used term in the world of technology. You may be wondering what this term actually means and what purposes these devices serve. Odds are, you’re already familiar with MEMs devices and don’t even know it. After all, this technology is used just about everywhere these days. Here is what you need…

-

5 Key Features of Factory Automation Software for Wet Benches

Are you having issues managing your wet benches? Factory automation software could be the solution your business needs. Integrating the right software into your wet benches has numerous benefits. Read on to learn about five key features and see the difference it will make in your day-to-day operations. 1. Collects Accurate Data Wet benches are…

-

The Key Advantages of Automation in Health Care

Robots are taking over many aspects of our lives. When it comes to the job market, automation is seen as a threat to some. When it comes to automation in health care, it’s for the greater good. Numerous benefits and advancements in health care will come through robots. Scientists are able to research more effectively…