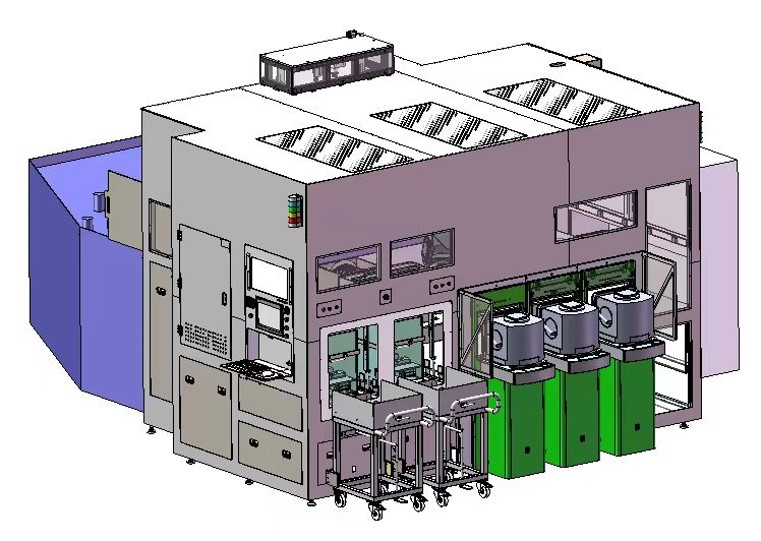

SA provides standard and custom solutions to single wafer processing such as CO2 wafer cleaning, EFEM, and other custom solutions. Below are our CO2 wafer cleaning and EFEM systems out in the field. For custom single wafer projects or for further information on these systems, please Contact Us!

Standard Features

- Cassette to Cassette Wafer Handling

- Automated Wafer Mapping

- Automated Wafer Pre-Alignment

- Closed Loop Low Pressure Chamber Controls

- Closed Loop Chuck Temperature Controls

- Closed Loop Chamber Temperature Controls

- Closed Loop Dew Point Controls Down to 60°C

- Programmable Chuck Controls

- Wafer Raster Scanning Speed Controls

- 0-360 degrees Wafer Cleaning

- Multi-step Cleaning Processing

- Nozzle Arm Speed Controls

- Leak Free Chamber Design

- Chamber and External Equipment

- ESD Controls

Benefits

- Solvent and Aqueous Free Wafer Processing

- Cleaning Down to 120nm

- Damaging-free of Fragile Devices

- 50mm to 300mm

- Parallel-wafer Size Processing

- Thin and Thick Wafer Processing

- Optimized Process Performance

- Dry in-Dry Out Process

- Class 10 Environment

- Off the Shelf Hardware Platform

- Maximum Reliability, Maintenance Friendly

- Lowest Cost of Ownership

- Wafer Data Reporting

- 100% GEM Compliant

- Compliant Standards CE, NFPA, NEC, SEMI S2, S8

Flexible Options

- 200mm and 300mm Load Ports

- OCR Reader

- Mobile Robot Load/Unload

- MES/SCADA Interface

- Tool Lockout on SPC Rule Violation

- Unlimited Automation Options

Industries

- Semiconductor

- MEMS

- Micro/Nano Electronics

- Compund Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLED

- Optics

Applications

- Wafer Cleaning

- Mask Cleaning

- Photo Resist Strip

- Metal Lift-Off

- Metallic Fence Removal

- Metallic Veil Removal

- Post Ion Milling

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping, and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated, and Manual

- Bulk Chemical and Solvent Distribution Systems

- Bulk Chemical and Solvent Waste Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- FAB Automation, Tool Automation

- Equipment-Host Connectivity Solutions via (GEM and non-GEM Complaint Tools)

- OEM Reconditioning and Upgrades

- Applications Engineering

Standard Features

- External Ion Controls

- Automatic Wafer Sampling Feature

- Proprietary End Effector Reduced Handling Marks

- <10 Sec. Exposure to Air

- Repeatable Wafer Exposure to Air

- High Accuracy Positioning

- Optimized Pick and Place Wafer Handling

- Optimized Inspection Features

- 50% Less Process Tim vs Manual Operation

- Dedicated Single Wafer Handling Robot

- Dual 6-Axis Robots with High Accuracy and Smooth Motion

- Flexible Design in a Compact Footprint

- DSP Process Tool Interface-Multi Protocols are Available

- 100% GEM300 Compliant

Benefits

- Low Operating Cost

- Reduced Labor Cost by 10x

- High Throughput with Process Repeatability

- Eliminate Misprocessing by Manual Operation

- Eliminate Wafer Breakage by Manual Wafer Handling

Flexible Options

- Custom Configuration

- 50mm to 300mm Wafers

- Unlimited Automation

Industries

- Semiconductor

- MEMS

- Micro/Nano Electronics

- Compund Semiconductor

- Disk Drive

- Bio/Medical Devices

- Photonics

- Aerospace

- Automotive

- LED/OLED

- Optics

Applications

- Wafer Cleaning

- Mask Cleaning

- Photo Resist Strip

- Metal Lift-Off

- Metallic Fence Removal

- Metallic Veil Removal

- Post Ion Milling

- Special Applications Engineering

Products and Services

- Wafer/Substrate Surface Cleaning, Etching, Plating, Stripping, and Texturing Equipment

- Batch and Single Wafer/Substrates

- Fully Automated, Semi Automated, and Manual

- Bulk Chemical and Solvent Distribution Systems

- Bulk Chemical and Solvent Waste Recovery Systems

- Bulk Chemical Mix and Distribution Systems

- FAB Automation, Tool Automation

- Equipment-Host Connectivity Solutions via (GEM and non-GEM Complaint Tools)

- OEM Reconditioning and Upgrades

- Applications Engineering